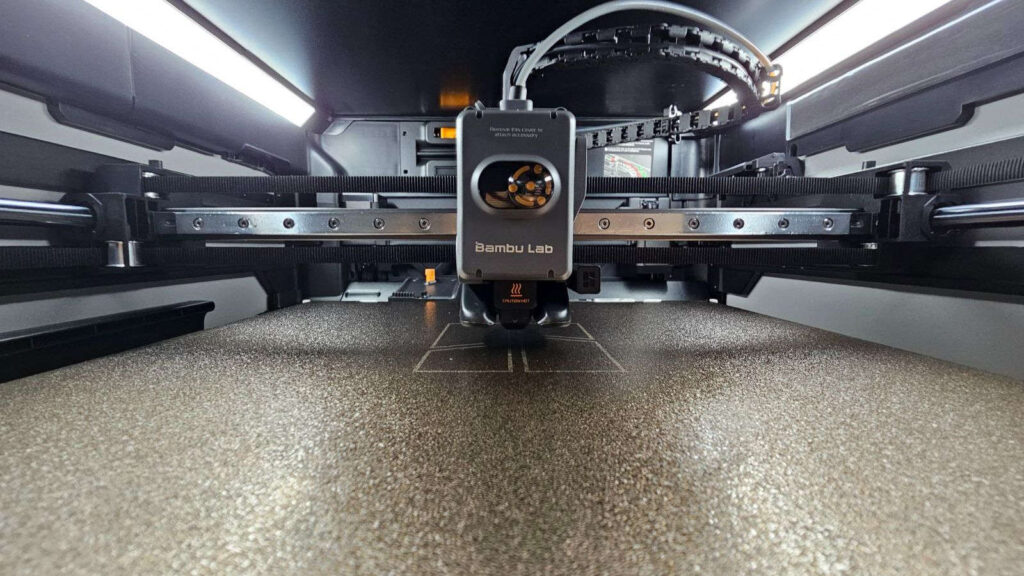

Here at CircuitWorx, we are continually looking for ways to refine our processes and enhance the services we provide. A key part of the product development journey is the ability to move efficiently from an initial concept to a functional prototype. To that end, we’re pleased to announce a new arrival in our workshop: the Bambu Lab H2S 3D Printer.

This new system joins our trusted X1 Carbon printer, expanding our in-house rapid prototyping capabilities. This investment allows us to offer our clients quicker turnaround times, higher precision, and a wider range of possibilities for projects that require custom mechanical parts and enclosures.

The Critical Role of Prototyping

Any experienced product developer knows that the prototyping and pre-production stages are vital. Attempting to move directly to volume manufacturing without thoroughly proving a design can be a costly error. Building representative prototypes provides the crucial opportunity to test a design, validate its fit, form, and function, and resolve any performance or compliance issues well before committing to full-scale production.

Our enhanced 3D printing setup directly supports this critical phase of development, allowing us to help our clients transform their ideas into tangible models faster than ever.

Expanded Applications and In-House Integration

Having this technology on-site at our Hampshire facility is about more than just convenience; it’s about providing a more integrated and responsive service. The new printer expands our capabilities in several key areas:

• Product Design Prototypes: We can quickly produce tangible models that allow for the physical validation of a design’s fit, form, and function. This iterative process is fundamental to successful product design and helps de-risk the move to production tooling.

• Custom Test Rig Enclosures: As part of our comprehensive engineering support, we often build customised test rigs and procedures. The ability to print bespoke housings allows us to create organised, secure, and robust testing setups for the products we design and manufacture.

• One-off PCB Enclosures: During electronics development, protecting prototype boards is essential. We can now rapidly produce reliable, custom-fit enclosures for one-off and low-volume prototype PCB assemblies, which is a core part of our service offering.

• Laser Engraving: The new system also includes laser engraving capabilities, enabling us to add personalisation, branding, and other professional finishing touches to parts and enclosures.

Strengthening Our End-to-End Service

At CircuitWorx, we offer an end-to-end service that takes a product from initial concept right through to volume production. Our services cover everything from electronic circuit design and PCB layout to full box-build and mechanical assembly. The expansion of our 3D printing capabilities strengthens this integrated approach.

Whether we are fitting a PCBA into a small enclosure or building a complex electro-mechanical assembly, having advanced in-house facilities for producing custom plastic parts is a significant advantage. This allows us to maintain control over quality and timelines, providing the simplicity of a single point of contact for the entire product manufacturing process. This capability is another tool that helps our professional engineers troubleshoot, suggest enhancements, and make your product the best it can be.

If you have a project that could benefit from our enhanced rapid prototyping and integrated design and manufacturing services, our team is here to discuss your requirements.